Nuclear Power Plant Aging Research CenterMaterial Technology Group

The metallic materials used in nuclear power plants are subject to corrosion in high temperature water, as well as degradation due to neutron irradiation. For this reason, it is necessary to elucidate those degradation mechanisms in order to ensure the long-term safety of power plants.

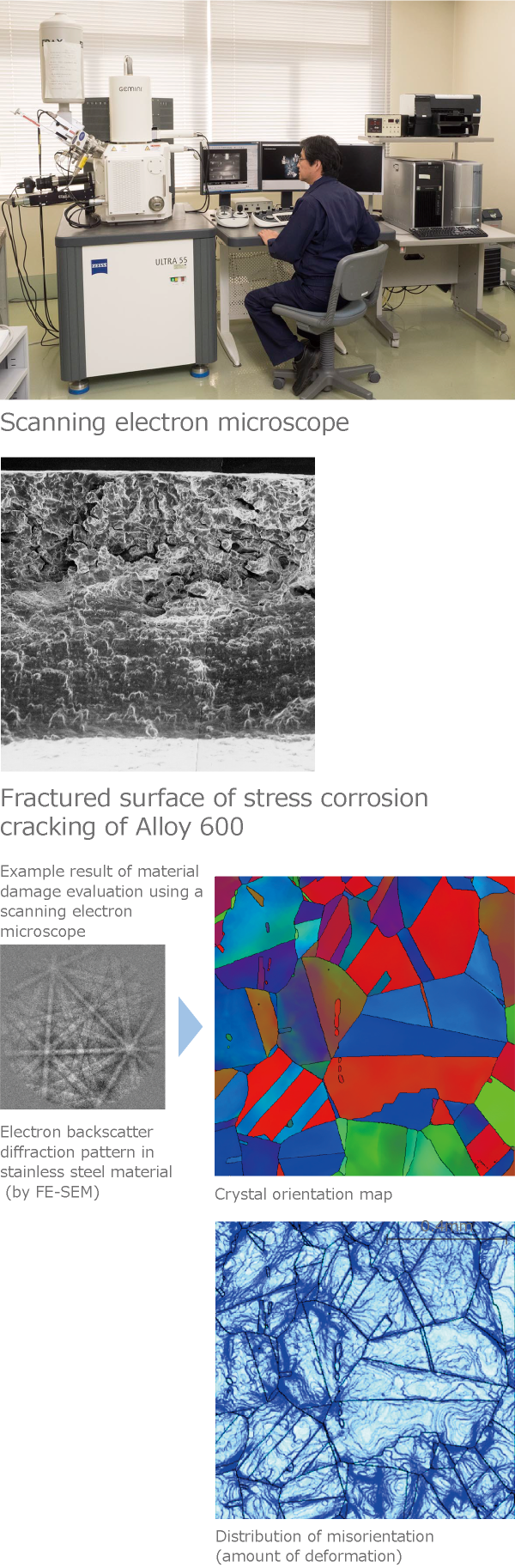

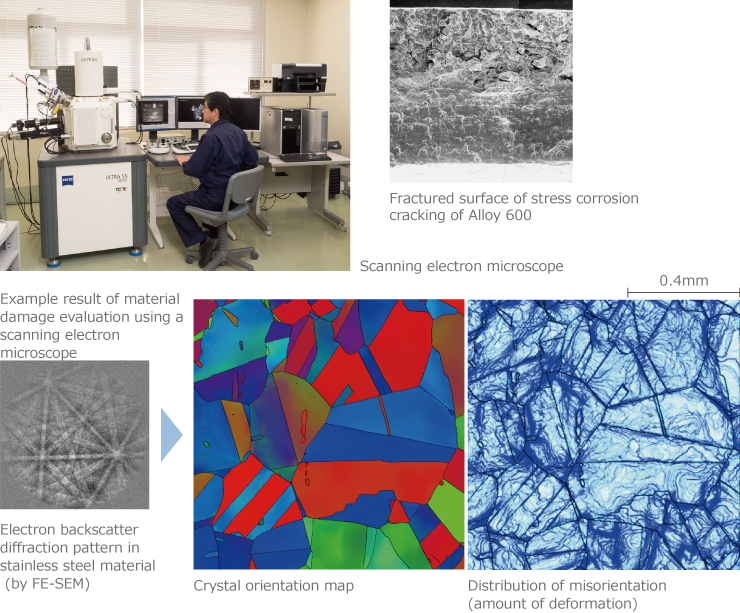

The Material Technology Group is carrying out mechanical and corrosion experiments using both the actual and simulated materials of nickel-based alloys, stainless steels, and low-alloy steels, which are the main structural materials used in nuclear power plant pipes and structures. Since October 2010, the Group has been committed to observation and analysis using the “Hot Labo” installed by KEPCO in Fugen Decommissioning Engineering Center of Japan Atomic Energy Agency. Also, through material characterization and numerical analysis for assessing crack propagation, the Group is involved in the research for elucidation of the mechanism of corrosion, fatigue and irradiation damage on aged structural materials and the prediction of material degradation.

Furthermore, the Group is playing the role of specialist doctor of nuclear power plants; thereby the Group is investigating the cause of failure actually occurring in equipment and pipes.As a “specialist doctor” for nuclear power plants, the Group is investigating the causes of actual failures occurring on equipment and piping in the nuclear power plants.

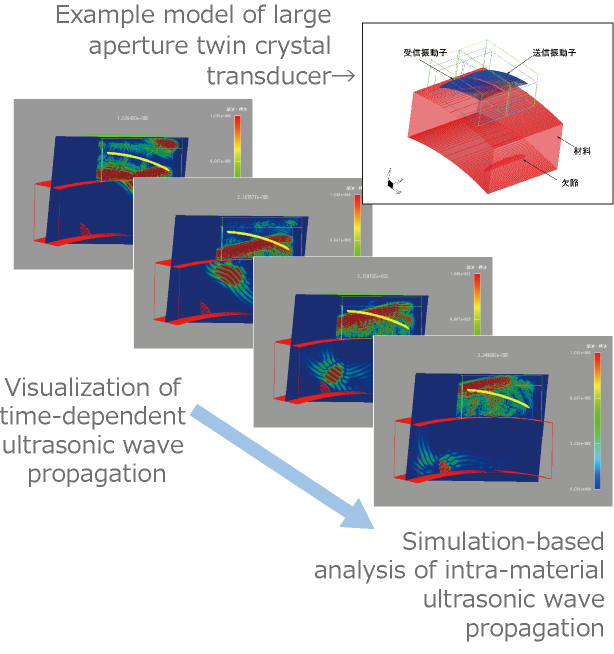

The Group is engaged in the development of the non-destructive testing techniques that can accurately detect and assess, at an earlier stage, the extent of aging in the power plant components and materials that are important to plant safety.

Corrosion Team

Irradiation Team

Inspection Team

Development of non-destructive testing techniques or metal materials

Key Achievements – Books & Brochures

-

Radiation and Structural Changes in Steel Reactor Vessels,

Radiation and Structural Changes in Steel Reactor Vessels,

INSS, 2001 -

Initiation and Prediction of Stress Corrosion Cracking for Alloy 600 in Primary Water of PWR,

Initiation and Prediction of Stress Corrosion Cracking for Alloy 600 in Primary Water of PWR,

INSS, 2008 -

Irradiation Behavior of Stainless Steels in Light Water Reactors,

Irradiation Behavior of Stainless Steels in Light Water Reactors,

INSS, 2009 -

SCC Behaviors of Stainless Steels in PWR Primary Environment,

SCC Behaviors of Stainless Steels in PWR Primary Environment,

INSS, 2012 -

Mechanisms of Material Degradation and Non-Destructive Evaluation in Light Water Reactors,

Mechanisms of Material Degradation and Non-Destructive Evaluation in Light Water Reactors,

INSS, 2002

Key Achievements

-

Automatic ultrasonic flaw detection device has been developed using a large aperture twin crystal transducer; this device boasts greater ability to detect defects in the welds within the primary coolant piping. Applicability of this device has been reviewed on the site

-

Cable aging diagnosis technique whose usefulness has been ascertained in Japan’s state-sponsored research project